Lucia Lee

Last update: 10/07/2025

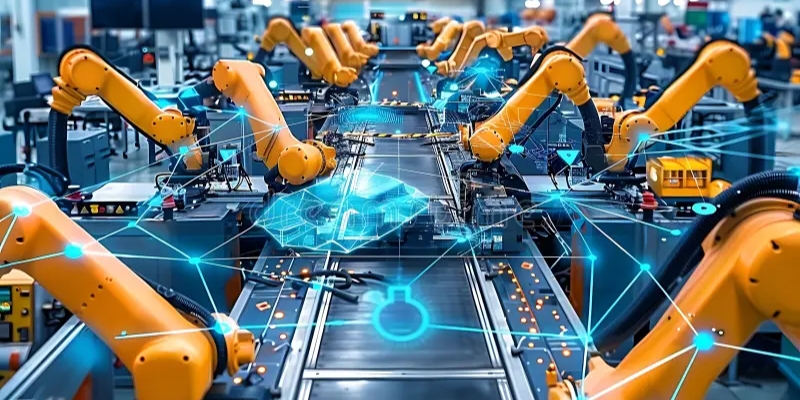

Automation in manufacturing has been around for decades, but it’s the use of AI for robotic automation in manufacturing that’s truly taking it to the next level. By combining the speed and precision of robotics with the intelligence of artificial intelligence, manufacturers are transforming everything from production lines to predictive maintenance. In this post, we’ll explore what magic happens on the factory floor when AI meets robotics - and why it matters more than ever.

To understand the power of AI for robotic automation in manufacturing, it's important to first distinguish between two core technologies: Artificial Intelligence (AI) and Robotics.

Artificial intelligence refers to computer systems that can analyze data, recognize patterns, learn from experience, and make decisions in a way that mimics human intelligence. It’s an umbrella term that includes AI technologies - such as machine learning, computer vision, and natural language processing - that give machines the ability to “see,” “understand,” and “respond” much like a human would. Think of AI as the brain behind the machine—giving it the power to do what once seemed impossible.

Robotics, on the other hand, is about building physical machines - robots - that can interact with the real world. These machines are designed to perform mechanical tasks like picking, welding, or moving parts. Traditional robots operate based on predefined instructions, using sensors and actuators to perform tasks with speed and precision.

When AI is integrated into robotics, the result is a system that is not just programmable but intelligent. Instead of relying solely on static commands, AI-enabled robots can gather data from their environment, adapt to unexpected changes, and make decisions in real time. In essence, AI gives robots the ability to learn and evolve, making robotic automation more flexible, autonomous, and efficient than ever before. This synergy is transforming manufacturing from rigid, rule-based systems to smart, adaptive, and continuously improving operations.

Also read: Computer Vision-Powered Robots: Benefits, Applications & More

With the integration of AI, the role of robots is no longer limited to repetitive tasks and rigid programming. Let’s explore how AI is making robotic systems more intelligent, adaptable, and collaborative.

Assembly line automation

Assembly lines are the lifeblood of manufacturing businesses, and they are becoming faster, smarter, and more flexible thanks to AI-powered robotic automation. Unlike traditional robots that simply repeat predefined motions, AI systems can adapt in real time. Whether it’s switching between product variants, adjusting for minor misalignments, or recalibrating after a disruption, AI-powered robots for assembly lines can make decisions on the fly. The result? Faster cycle times, fewer errors, and production lines that keep moving - even when the unexpected happens.

Assembly line automation

Quality inspection

When it comes to quality control, precision is everything - and AI for robotic automation in manufacturing delivers it with speed and consistency that humans can’t match. By combining high-resolution imaging with AI algorithms, robotic systems can identify surface-level defects like scratches, dents, or misprints in milliseconds. These inspections aren’t limited to visual flaws either; machine vision for robotic quality inspection can also spot inconsistencies in shape, texture, or component alignment. For manufacturers, this means catching issues before they become costly recalls - and doing so without slowing down the line.

Defect detection

What if your robots could catch mistakes as soon as they happen - and correct them instantly? That’s exactly what real-time defect detection using AI in robotics delivers. These systems analyze visual and sensor data frame-by-frame during the manufacturing process. If a defect or anomaly is detected - like a missing part or irregular weld - the system flags it immediately or halts the process for correction. This cuts down on rework and prevents defective items from moving down the line, keeping quality high and waste low.

Defect detection

Predictive maintenance

Waiting for a machine to fail before fixing it often means resources going down the drain. To minimize this, leveraging predictive maintenance is the best bet. AI for robotic automation in manufacturing helps monitor equipment health and predict when a component might break down - before it actually does.

Sensors embedded in robotic joints, motors, and control units feed continuous data into machine learning models trained to detect early warning signs. Maintenance teams are then alerted to fix the issue ahead of time, reducing unplanned downtime and avoiding expensive repairs. It's like giving robots their own early warning system.

Collaborative robots

Gone are the days when robots had to be separated from people. Collaborative robots (cobots) with AI integration are designed to work side-by-side with human operators safely and efficiently. These cobots use AI to interpret their environment, sense human presence, and adjust their behavior accordingly. For example, if a worker steps closer, the cobot slows down or changes its path. Some can even learn tasks by watching humans perform them without any complex programming needed. This opens up new possibilities for small-batch production, assembly customization, and a more flexible workforce.

Also read: AI For Robotic Automation: Everything You Need To Know

Precision robotics

Whether it's placing microchips on a circuit board or welding intricate automotive frames, AI-driven robotic arms for precision tasks bring unmatched accuracy to the manufacturing floor. These arms aren’t just fast—they’re intelligent. Powered by AI, they can fine-tune their positioning, force, and timing based on real-time feedback. They can also adapt mid-process if needed, maintaining tight tolerances even in high-speed operations. This level of control allows manufacturers to meet demanding quality standards at scale, without sacrificing efficiency.

Material handling

Material movement may seem routine, but it’s a vital part of any manufacturing operation - and AI in autonomous material handling robots is making it smarter than ever. These self-navigating bots use AI to plan routes, avoid obstacles, and prioritize deliveries in real time. No more waiting for forklifts or relying on static conveyor belts. Whether transporting components to workstations or delivering finished goods to the warehouse, these robots work around the clock, reduce human labor, and increase throughput - all while learning from every trip to optimize the next.

As manufacturers face growing pressure to produce faster, safer, and more sustainably, AI is stepping in as a game-changer. Let’s discover the various benefits that AI for robotic automation in manufacturing has to offer.

Enhanced product quality

With AI integrated into production lines, product quality becomes more consistent and reliable. AI systems can identify surface flaws, dimensional inconsistencies, or misalignments at various stages of production. This real-time feedback prevents defective products from advancing and ensures that only items meeting quality benchmarks reach customers. The result is a stronger brand reputation and reduced costs associated with returns and warranty claims.

Enhanced product quality

Increased efficiency and productivity

AI has dramatically enhanced manufacturing efficiency by enabling machines to operate 24/7 without fatigue or slowdowns. Unlike human workers, autonomous robots in factories can perform repetitive, high-speed tasks with consistent accuracy, resulting in faster production cycles and reduced downtime. These improvements are particularly valuable in high-demand sectors, where even small efficiency gains lead to significant competitive advantages. The integration of robot process automation (RPA) allows manufacturers to scale operations without compromising performance or product consistency.

Enhanced accuracy and precision

One of the most critical benefits of intelligent robotics systems is their unmatched precision in handling complex tasks. AI algorithms help robots detect micro-defects and deviations that the human eye might miss, significantly reducing errors. In quality control, smart manufacturing systems powered by AI can inspect products in real-time, ensuring that every item meets stringent specifications. This consistency improves customer satisfaction and reduces waste due to rework or defective goods being shipped.

Also read: Agentic AI in Robotics: Everything You Need to Know

Improved safety in hazardous environments

In industries dealing with heat, chemicals, or heavy machinery, human-robot collaboration enhances safety by offloading dangerous tasks to AI-powered robots. These machines can perform in conditions unsafe for humans, such as toxic or high-temperature environments. Adaptive robots with AI for flexible manufacturing are especially useful, as they adjust their responses to changing surroundings and human input, ensuring smooth collaboration while minimizing risk.

Cost reduction

While adopting industrial automation and AI requires upfront investment, it’s a worthwhile investment that leads to long-term cost savings. AI systems reduce labor costs, improve resource utilization, and minimize machine downtime through predictive maintenance. By identifying wear and tear before failure occurs, AI prevents costly breakdowns and prolongs equipment lifespan. Over time, this AI-based production optimization helps businesses operate leaner and more profitably.

Data-driven decision making

By using AI for robotic automation in manufacturing, you can turn massive datasets into actionable insights. AI systems can process and analyze production metrics in real time, allowing you to make fast, informed decisions that optimize business efficiency and productivity in both short and long terms.

Sustainability

Modern manufacturers are under growing pressure to adopt sustainable practices. AI supports these goals by minimizing waste, optimizing energy consumption, and ensuring efficient use of raw materials. AI-based production optimization ensures that every process is as resource-efficient as possible. By leveraging intelligent robotics systems and automation, factories can meet sustainability targets without sacrificing productivity or profitability.

While AI for robotic automation in manufacturing offers undeniable benefits, its implementation is not without challenges. Understanding the barriers below is the first step toward building resilient, future-ready automation strategies.

Limited access to domain-specific data

One of the foundational challenges in implementing AI in manufacturing robotics is the lack of domain-specific, high-quality datasets. For AI algorithms to perform reliably in complex factory environments, they need to be trained on real-world data reflective of specific machines, workflows, and conditions. However, in many industries - especially highly specialized ones - such data is either scarce, siloed, or difficult to obtain due to privacy concerns or proprietary restrictions. Without it, training accurate and context-aware robotic models becomes difficult, limiting performance and reliability.

Complexity of processing heterogeneous data

Manufacturing environments use a variety of sensors to monitor temperature, pressure, motion, audio signals, visual inputs, and more. Integrating and interpreting this diverse data into a unified AI system is a major technical hurdle.

Unlike a single-data-source system, AI for robotic automation in manufacturing must combine structured and unstructured inputs through advanced sensor fusion in robotics. Ensuring consistency and real-time responsiveness across multiple data formats (like video, thermal imaging, vibration readings, etc.) requires sophisticated architectures and high processing power.

Complexity of processing heterogeneous data

Annotation and labeling bottlenecks

Building effective AI models for robotic automation also demands precise data labeling, particularly for tasks like quality inspection or predictive maintenance. For instance, to teach a robotic arm to detect subtle defects, engineers must provide well-labeled visual examples of what qualifies as a defect. Labeling such datasets - especially across image, video, and sensor data - is time-intensive and expensive. While auto-labeling tools exist, their accuracy still lags behind manual efforts, slowing down model development.

Technical limitations in unpredictable environments

AI models in industrial settings often struggle with generalization. That is, they may perform well in controlled environments but falter when exposed to new variables - such as machine wear, human error, or workflow changes. Tasks that require common-sense reasoning, situational awareness, or decision-making under uncertainty remain out of reach for many current AI systems. This makes it challenging to rely solely on AI for robotic automation in manufacturing in dynamic or unpredictable factory settings.

Privacy and data security risks

Robots powered by AI often collect and analyze sensitive operational data - like production performance, employee workflows, or proprietary manufacturing processes. As these systems become more connected (especially via cloud platforms), they introduce cybersecurity vulnerabilities. A breach could lead not only to data theft but also to malicious control over autonomous machinery. Manufacturers must therefore implement robust security frameworks to safeguard data while ensuring compliance with evolving data protection regulations.

Also read: 11 Data Security Solutions To Safeguard Your Critical Data

Ethical concerns and workforce impact

As AI for robotic automation in manufacturing advances, it naturally raises ethical concerns - particularly around job displacement. While AI can take over repetitive or hazardous tasks, there's growing anxiety about reduced roles for human workers.

Furthermore, transparency in AI decision-making is still limited; explaining why a robot made a specific move or flagged a product as defective isn’t always straightforward. This lack of explainability, coupled with automation's societal impact, highlights the need for clear policies around ethics, accountability, and retraining programs for affected workers.

Human-robot interaction challenges

In collaborative environments where humans and AI-powered robots work side by side (such as with cobots), understanding and adapting to unpredictable human behavior is essential. However, AI still struggles with interpreting non-verbal cues, emotional expressions, or spontaneous changes in human workflow. Without sufficient safeguards, these limitations can pose risks to both productivity and safety. Developing robots that are not only functionally smart but socially aware remains an ongoing research priority.

AI is no longer a futuristic concept in manufacturing - it’s a present-day game changer. From predictive maintenance to real-time defect detection, AI for robotic automation in manufacturing is redefining how factories operate, compete, and grow.

At Sky Solution, we specialize in delivering AI for robotics solutions tailored to the needs of modern manufacturing. Whether you're optimizing assembly lines, enhancing quality control, or exploring human-robot collaboration, our intelligent systems are designed to help you build smarter, faster, and more resilient operations.

Ready to future-proof your factory floor? Reach out to Sky Solution today and discover how our AI-driven robotics can accelerate your journey toward intelligent automation.