Lucia Lee

Last update: 19/11/2025

Unexpected breakdowns don’t just slow operations - they drain budgets, frustrate customers, and throw entire workflows off balance. That’s why predictive maintenance has become mission-critical for businesses that rely on equipment running smoothly and consistently.

But as machines get more complex and the cost of downtime climbs, traditional inspections can’t keep up. This is where computer vision for predictive maintenance comes in. By interpreting real-time visual data, it spots anomalies earlier, catches issues humans might miss, and helps teams take action before small problems turn into expensive failures. In this post, we’ll break down how computer vision is reshaping predictive maintenance and what it means for smarter, more resilient operations.

Predictive maintenance is a proactive maintenance strategy that uses real-time data to understand the health of equipment and anticipate issues before they disrupt operations. Instead of relying on fixed schedules or waiting for machines to fail, businesses use advanced technologies to continuously monitor how their assets are performing, forecast the future state of equipment, and flag early warning signs that traditional inspections may miss. This means the right teams get the right information at the right moment - long before a minor issue becomes a costly failure.

Computer vision is a branch of artificial intelligence (AI) that enables machines to interpret and analyze visual data from cameras, sensors, and video streams. It powers tasks like defect detection, anomaly detection, and pattern recognition by extracting meaningful insights from images in real time.

In predictive maintenance, computer vision serves as a continuous visual layer that complements traditional sensor-based monitoring. Through real-time monitoring of equipment, it identifies physical indicators of degradation - such as cracks, misalignment, overheating, or abnormal movement - that are difficult to capture with vibration or temperature sensors alone.

High-resolution cameras, thermal imaging, and machine learning models work together to process visual data, detect anomalies, and provide a detailed understanding of a machine’s condition as it operates. Computer vision systems also integrate smoothly with IoT platforms, allowing visual insights to be combined with other operational data sources to build more accurate predictive models.

In this way, computer vision becomes a core technical component of predictive maintenance, offering continuous, detailed visibility into equipment health through advanced visual analysis.

The role of computer vision in predictive maintenance

Now let’s break down how computer vision turns raw visuals into reliable insights, powering automated inspection for maintenance.

Step 1: Capturing visual data

The process of computer vision for predictive maintenance begins with image acquisition. Cameras - whether RGB, thermal, or mounted on drones and robots - continuously record equipment as it operates. This provides the raw visual feed that the system will later analyze, often alongside other machine telemetry.

Step 2: Preparing the data for analysis

Before any model can interpret the visuals, the system performs data preprocessing. This involves correcting distortions, removing noise, normalizing lighting conditions, and structuring frames so they are consistent. Clean, stable inputs make the next stages far more accurate.

Step 3: Enhancing and interpreting the visuals

Next comes image processing, where software stabilizes footage, highlights regions of interest, sharpens edges, and extracts key visual features like textures, heat patterns, or small deformations. At this stage, visual inputs may also be combined with operational metrics using sensor data analysis to give a fuller picture of machine behavior.

Step 4: Detecting anomalies with AI models

Once the features are prepared, they are fed into deep learning models and other machine learning approaches. These models classify defects, detect unusual patterns, and generate anomaly scores. Known issues are handled with supervised learning, while unsupervised or few-shot techniques help identify rare or emerging failure types.

Step 5: Producing actionable outputs

Finally, the system transforms predictions into usable signals: alerts, visual heatmaps, or automated triggers for maintenance workflows. Rather than showing raw frames or isolated metrics, the output communicates exactly what needs attention and why, completing the full computer vision for predictive maintenance pipeline.

Computer vision is already transforming how organizations monitor, assess, and maintain critical assets. Here are some of the most impactful use cases of computer vision for predictive maintenance across industries:

Monitoring wear and surface degradation over time

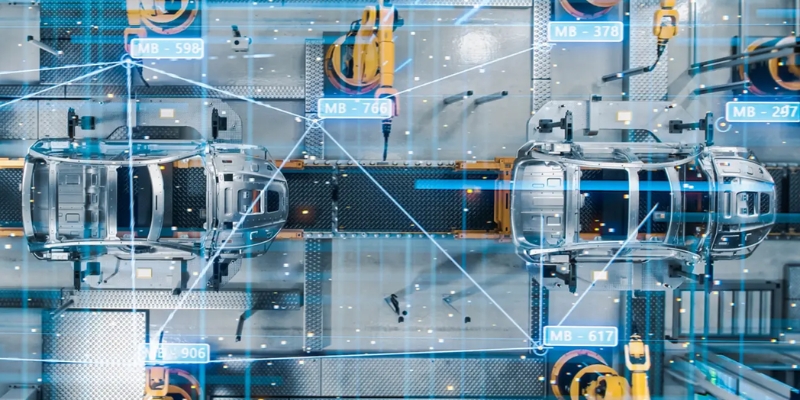

In manufacturing environments, continuous monitoring of equipment surfaces is essential for preventing small defects from derailing production. With visual anomaly detection in manufacturing, high-resolution cameras capture detailed images of gears, conveyor belts, and robotic joints.

Deep learning models perform vibration and surface defect analysis, spotting corrosion or coating deterioration long before they trigger system failures. This form of early-stage fault detection using CV enhances both condition monitoring and long-term equipment health assessment, giving teams a clearer picture of component lifespan.

Automotive plants, for example, use equipment condition monitoring with AI to forecast when stamping machines or robotic welders will require attention - supporting smarter maintenance scheduling and reducing unexpected downtime.

Monitoring wear and surface degradation over time

Also read: Computer Vision in Automated Quality Control: Ultimate Guide

Thermal imaging and heat anomaly detection

In the energy sector, overheating is one of the most common precursors to equipment failure. By integrating thermal imaging for predictive maintenance into routine inspections, operators can detect abnormal heat signatures in transformers, turbine housings, or power distribution units.

CV-powered thermal cameras identify hotspots that signal insulation breakdown or electrical imbalance, enabling fast fault detection without direct human contact. This approach blends anomaly detection with sensorless monitoring via computer vision, since visual thermal data alone can reveal issues well before traditional sensors do. Wind farms and solar plants now rely on real-time machine health assessment powered by thermal feeds to keep their assets running safely and efficiently.

Real-time behavior and motion analysis

Many issues in logistics machinery - such as conveyors, robotic pickers, or automated sorting arms - stem from subtle motion irregularities. Computer vision for predictive maintenance uses action-recognition CV models to track how these machines move, rotate, and operate under different loads. When a robotic arm begins to jitter or a conveyor belt shows periodic stutter, the system immediately flags deviations from normal patterns.

By analyzing motion sequences over time, CV models can forecast when a component might seize, misalign, or degrade. Large fulfillment centers apply these techniques daily to ensure seamless industrial automation, prevent workflow bottlenecks, and plan interventions ahead of failure.

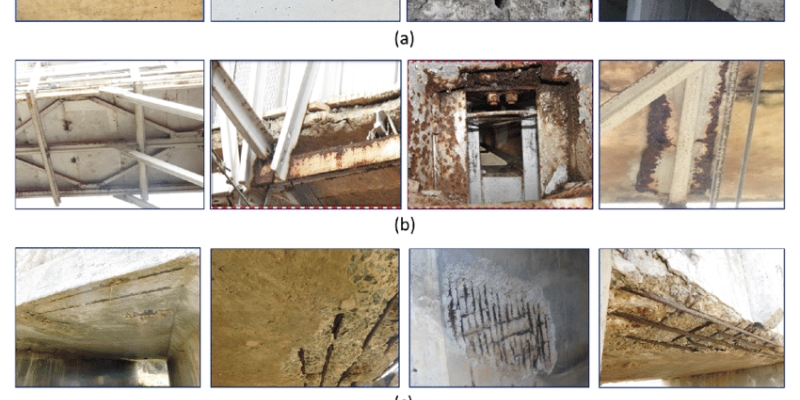

Structural crack, deformation, and corrosion detection

Construction equipment such as cranes, bulldozers, and excavators operates under extreme stress, making structural integrity critical. Computer vision models perform visual defect identification by examining high-resolution imagery of beams, hydraulic arms, and load-bearing joints. Techniques like semantic segmentation highlight even the smallest cracks or rust patches at the pixel level, enabling extremely accurate heavy machinery.

Drone-based imaging has become standard in major construction projects, providing sensorless monitoring via computer vision for difficult-to-reach locations. By spotting defects early, companies improve equipment health assessment, maintain safety compliance, and rely on stronger predictive analytics to guide part replacements or overhauls.

Structural crack, deformation, and corrosion detection

Leak, pressure, and flow irregularity detection

Pipelines, valves, and drilling rigs are prone to leaks that humans often cannot detect until too late. Using infrared imaging combined with CV-based anomaly detection, operators can instantly identify gas, steam, or fluid escaping from compromised joints or corroded sections. This type of equipment condition monitoring with AI plays a vital role in preventing environmental hazards and costly shutdowns.

High-risk offshore facilities use real-time machine health assessment to monitor pipeline pressure visually, allowing them to react fast when a leak begins forming. When paired with predictive analytics, these insights help maintenance teams decide when to perform targeted repairs, schedule shutdowns, or replace worn components before a failure cascades into a larger safety issue.

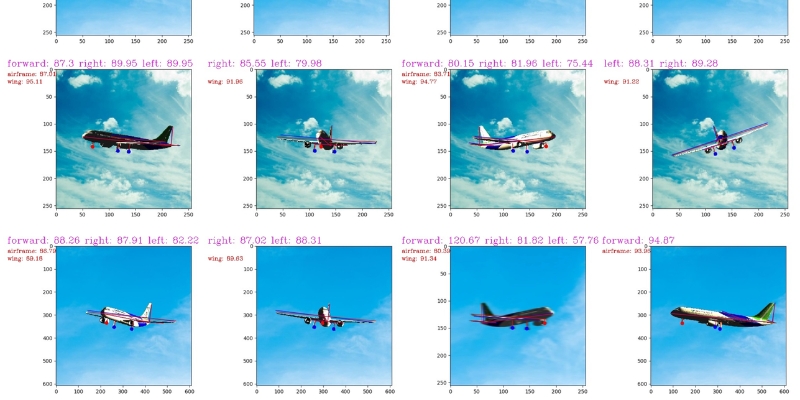

Object tracking and asset visibility for operational reliability

Public infrastructure agencies operate high-value assets - such as aircraft, rail systems, and emergency equipment - where part misplacement or misuse can lead to severe operational delays. CV-based object detection and tracking support industrial automation by monitoring tools, components, and maintenance routines in real time.

Airports, for example, use vision systems for equipment health assessment of aircraft fuselages and landing gear, identifying dents or surface anomalies that require urgent attention. This also forms the backbone of predictive analytics for industrial equipment, helping teams understand historical defect patterns and prevent recurring issues. Through computer vision for predictive maintenance, these agencies keep essential infrastructure safer, more reliable, and in service longer.

Object tracking and asset visibility for operational reliability

Computer vision elevates predictive maintenance from a reactive, labor-intensive process to a proactive, intelligence-driven strategy. Let’s take a closer look at the key advantages of computer vision for predictive maintenance:

Dramatically reduced downtime

Unplanned downtime remains one of the most expensive operational risks. Computer vision for predictive maintenance minimizes that impact by spotting early warning signs long before failures occur. High-resolution imaging, anomaly detection, and automated visual inspection work together to surface issues like micro-cracks, overheating, or misalignments early, allowing teams to intervene before an outage cascades into production loss.

Smarter and more predictable maintenance scheduling

Instead of operating in crisis-response mode, teams can plan maintenance with precision. Computer vision provides real-time visibility into asset condition, enabling schedules that are stable and far less likely to be disrupted by last-minute emergencies. This keeps technicians focused on strategic, value-driven tasks rather than constant firefighting.

Lower user and operational disruption

Because visual insights reveal issues early, maintenance can be performed during planned downtime, low-usage periods, or off-hours. This is especially valuable for service providers managing equipment on behalf of customers, helping them cut user-impacted downtime, protect SLAs, and improve satisfaction across the board.

Extended equipment lifespan

Continuous visual monitoring helps organizations understand exactly how assets age and when they start showing stress, corrosion, or wear. With timely interventions, equipment avoids deeper damage and stays in optimal working condition for longer - reducing the frequency of replacements and major overhauls.

Significant cost reduction on repairs and operations

Catching problems early means issues are addressed when they’re still small and inexpensive. Instead of paying for emergency repairs, catastrophic failures, or overnight parts shipments, companies can resolve minor defects proactively. Computer vision also reduces the need for unnecessary part replacements by tying maintenance decisions to real asset conditions - not guesswork.

Improved resource allocation and operational efficiency

Computer vision systems monitor equipment continuously and autonomously, eliminating the need for repetitive manual inspections. Teams can focus their time on assets that truly require attention, improving overall labor efficiency. This automation also scales effortlessly across large facilities, remote sites, or multiple locations - something manual teams simply can’t achieve.

Enhanced safety and risk prevention

Safety issues often begin as subtle defects: a slightly warped beam, a hot motor casing, a small hydraulic leak. Computer vision detects these conditions long before they become hazards. Automated visual analysis reduces human error, keeps people away from dangerous inspection areas, and ensures compliance with safety standards - all while preventing accidents that would otherwise threaten employees and infrastructure.

Enhanced safety and risk prevention

Better inventory and spare-parts management

With accurate predictions of when components will fail, businesses no longer need to overstock spare parts “just in case.” Computer vision for predictive maintenance informs exactly when replacements will be needed, freeing capital, reducing waste, and tightening procurement cycles.

Stronger sustainability performance

Predictive maintenance supports sustainability efforts by detecting issues like leaks, inefficiencies, excessive waste, and abnormal energy usage. By preventing avoidable failures and reducing unnecessary replacements, computer vision lowers resource consumption and helps organizations stay aligned with environmental goals - whether reducing emissions, improving asset efficiency, or minimizing scrap.

Data-driven decision making across operations

Every visual inspection and every identified anomaly becomes part of a growing dataset. Over time, businesses gain a clearer understanding of long-term asset behavior, failure patterns, and environmental impacts. These insights lead to better decisions about maintenance strategy, equipment upgrades, process optimization, and capital planning.

Computer vision can transform how enterprises detect equipment issues - but deploying it in real operations is far from straightforward. Below are the key challenges of computer vision for predictive maintenance that businesses need to navigate for effective implementation.

Unreliable or inconsistent data

Predictive models depend on large volumes of clean, well-labeled visual data showing both normal and faulty conditions. However, in reality, imagery varies across sites, lighting shifts, camera replacements, and inconsistent annotation standards. Fault cases are especially scarce, making it difficult to train models with balanced examples. Without strict data collection protocols, annotation quality control, and strategies like augmentation or synthetic fault generation, model accuracy quickly degrades.

Environmental and operational variability

Small changes - dust, heat, shadows, new coatings, vibration - can distort what cameras capture. These variations cause data drift, resulting in false alarms or missed anomalies. Continuous calibration, preprocessing pipelines, and monitoring of input quality are required to maintain stable model performance.

Black-box predictions and low operator trust

Maintenance teams are unlikely to act on alerts they cannot understand. If the system can’t show why it flagged a potential failure, technicians default to manual checks. Explainability tools - such as heatmaps, segmentation masks, or temperature deltas - are critical to make AI outputs interpretable and actionable on the factory floor.

Integration hurdles across legacy infrastructure

Even the best model fails without seamless deployment. Many facilities rely on aging SCADA systems, fragmented IoT platforms, or closed industrial software. Connecting computer vision pipelines to CMMS, ERP, or edge devices introduces significant architectural work. Real-time processing may also require new hardware, improved bandwidth, and robust edge-cloud orchestration.

Privacy, security, and ethical considerations

Cameras inevitably capture proprietary assets - or even people. Organizations must address data governance, encryption, access control, and concerns about surveillance. Transparent communication is essential to ensure employees understand the system’s purpose and boundaries.

Computer vision is reshaping predictive maintenance - from how failures are detected to how decisions are made on the factory floor. As models grow more accurate and infrastructure becomes more edge-ready, businesses that adopt early will gain a meaningful operational advantage.

If you’re exploring how to bring computer vision into your maintenance strategy, Sky Solution can help you move from experimentation to real, scalable deployment. Contact us now for a free consultation on how our computer vision solutions can support your business.